© 2018

Zhangjiagang Hyd Machine Co., Ltd. All rights reserved.

sitemap | pvc pipe making machine | hdpe pipe making machine | pvc edge banding making machine | pvc mixer

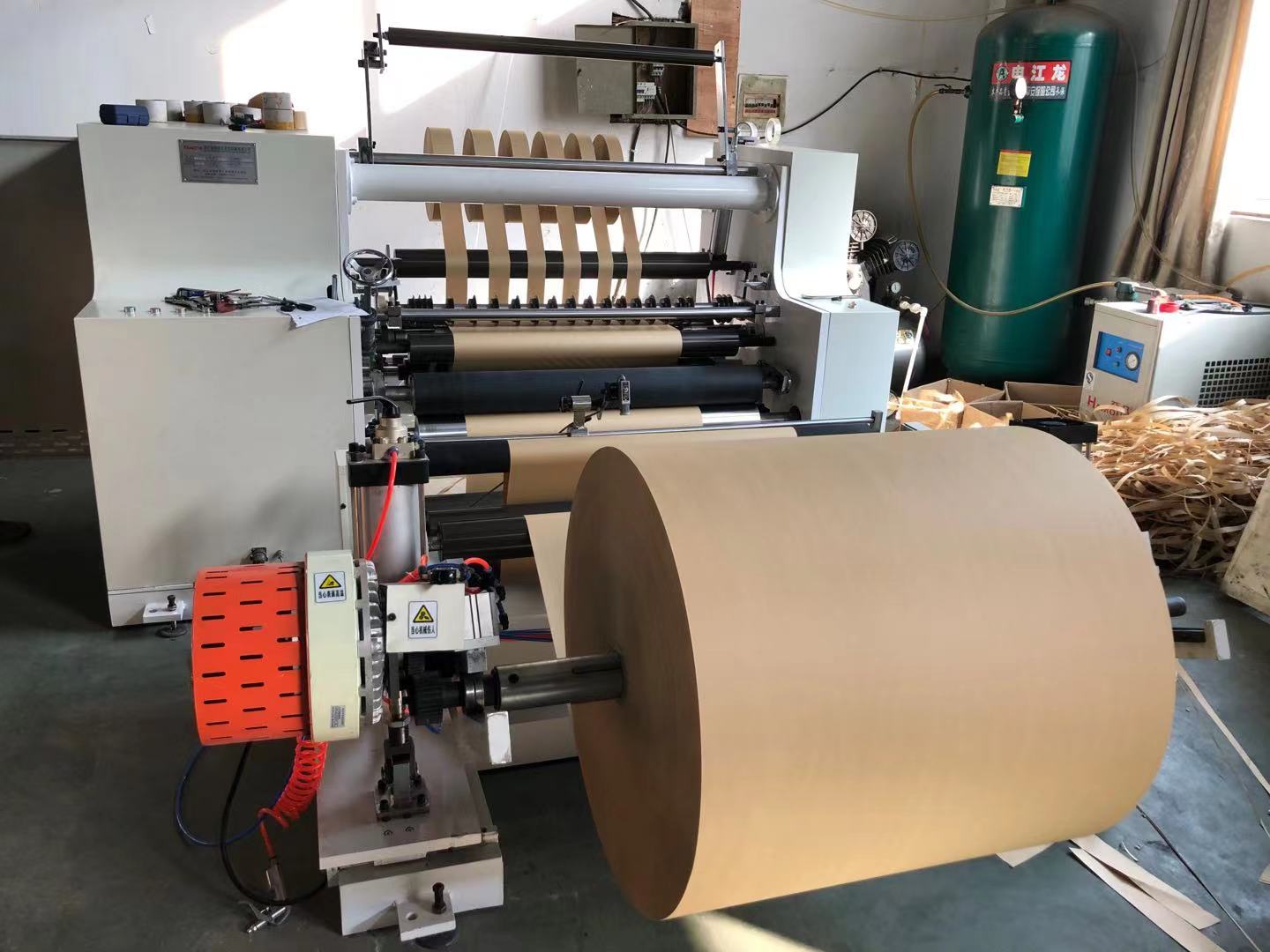

1.Main technical parameters

1 | Maximum diameter of unwinding | φ1300mm

|

2 | Maximum diameter of winding | φ600mm

|

3 | Winding width range | 100mm-700mm |

4 | Slitting width | 20mm-700mm |

5 | Diameter of the rewinding paper tube | 3 "(inner diameter φ76mm outer diameter φ92mm) |

6 | Highest mechanical speed | 280m/min |

7 | Maximum rewinding speed | 280m/min |

8 | Maximum score cutting speed | 280m/min |

9 | Width of the inner cavity of the machine | 1070mm |

10 | Correction accuracy | ≤0.40mm

|

11 | Tension setting range | 2 ~ 30kg |

12 | Unwinding magnetic powder tension | 200N.M |

13 | The winding motor power | 4kW-6 |

14 | Traction motor power | 5.5kW |

15 | Total machine power

| 15kw |

16 | Machine dimensions The weight of the machine | 3000 (L) ×2400 (W) ×1600mm (H)

|

17 | Suitable material | Film and composite film 12-180um,PE, PVC self-adhesive, paper, anodized aluminum film, aluminum plating film, aluminum foil

|

18 | Machine color | Gray (other colors are optional)

|

19 | The weight of the machine | 3000kg |

2. Description of the main parts

2.1 Unwinding Part

1 |

Structure | ●Independent rectifying unwinding rack ● pneumatic feeding, safety chuck locking ●LPC transverse rectifying mechanism ● Tension automatic control

|

2 |

Specification | ● Roll width range of 100 ~ 700 mm ● Unwinding diameter (Max) φ1300 mm ● Unwinding magnetic powder tension 200N.M ●LPC lateral deviation correction accuracy ± 0.4mm ● Maximum load of winding 600kg

|

3 |

Feature | ● With shaft pneumatic unwinding frame, fast and convenient. ● With LPC can ensure the rewinding neat ● Tension using magnetic powder by PLC automatic calculation of coil diameter automatic tension control, make the tension control of material film more scientific, more accurate ● Magnetic powder in the control of unwinding makes the tension control more gentle, no residual torque, tension control precision is high

|

2.2.Defelcting roll and guide roll

1 | Structure | ●The adjustment structure is manual ● One end of the deflection roller is adjusted up and down, and the other end is adjusted back and forth ● aligning roller, guide roller are using Hawalo bearing

|

2 |

Specification | ● Deflection roller diameter φ100 mm ● The length of the deflection roller is 750 mm ● Deviation range ±20 mm ● guide roller diameter φ100 mm ● Guide roller length 750 mm

|

3 |

Feature | ● Adjust the roll mechanism to adapt to different quality material film ● The roller into the action of balance, so that the machine without vibration source, smooth operation ● Adopt high precision bearing to make the roller stable when rotating at high speed and reduce the noise of the machine

|

1 |

Structure | ● AC vector frequency conversion drive ● synchronous belt drive ● Active traction roller adopts steel roller structure ● The rotating body adopts imported bearings ● Double roll to roll type, steel and soft combination ● Cots clutch, pressure adjustment by pneumatic components to complete

|

2 |

Specification | ● Drive roller diameter φ135 mm nitrile rubber shore (A) 70° ~ 75° Low rubber roller phi 130 mm ● The maximum pressure of the rubber roller 200kg ● Drive roller length 750 mm ● Roll dynamic balance accuracy ≤5g ● Traction motor power 5.5kW |

3 |

Feature | ● The traction device can block the unwinding tension and winding tension, so that the changes do not affect each other ● After the roller is balanced, the machine has no vibration source and runs smoothly ● The use of high grade bearings make the roller at high speed running smoothly, reduce the noise of the whole machine Adopt synchronous belt for transmission accuracy, smooth operation, at the same time reduces the noise in the whole machine ● The use of asynchronous servo motor drive, so that the system tension is stable, high transmission precision, stable and reliable operation |

2.4.Cutting Department

● Round knife cutting method ●The flat knife adopts the slotting roller to support the slitting ● The edge material in the slitting part is blown by the exhaust fan to the waste box for collection |

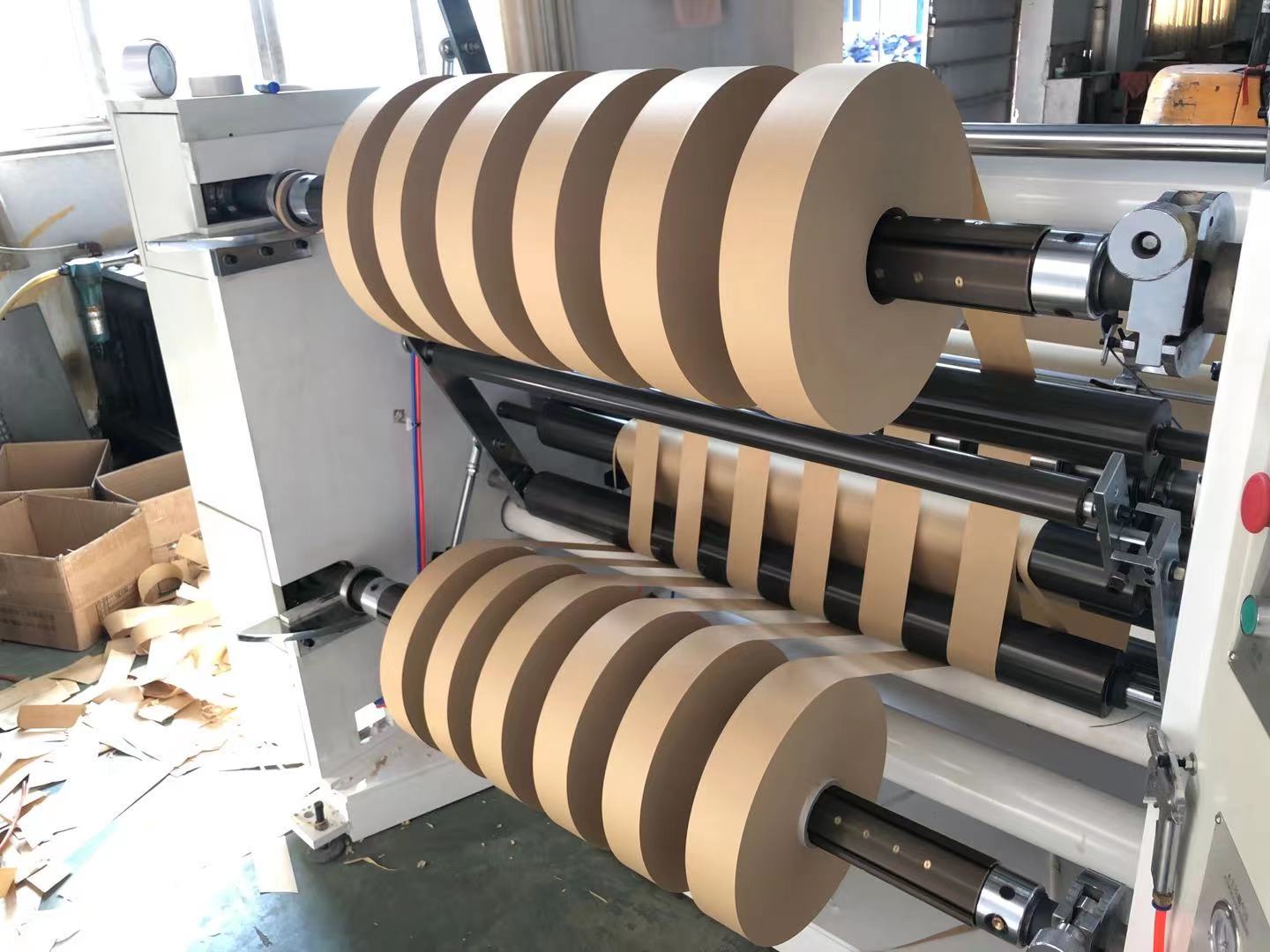

2.5.Winding roller

1 | Structure | ● Swing arm rotary frame ● clutch pressure for pneumatic form |

2 | Specification | ● Roller diameter φ60mm ● The roll surface is 750mm long |

3 | Feature | ● Pressure changes with diameter, conducive to winding neatly ● Suitable for uneven thickness of the substrate

|

2.6.Receiving department

1 |

Structure | ● Double air expansion shaft up and down winding ● Automatic tension control ● Support arm control using pneumatic ● Motor active winding. |

2 | Specification | ● Winding diameter (Max) φ600 mm ● Winding motor power 4kw-6 ● Maximum load of winding 300kg |

3 |

Feature | ● Air expansion shaft can adapt to a wide range of materials, coiling to maintain stable tension of the substrate. ● Tension is automatically calculated by PLC coil diameter through the electrical proportional valve to achieve automatic control, making the tension control of material film more scientific and accurate ● Motor active winding makes the tension control range is large, no residual torque, tension control precision is high |

2.7.Discharging device

● Unloading device, the rewinding reel can be opened single side cantilever type, can also be unloaded whole shaft. |

2.8.Frame part

● Steel plate, steel plate thickness of 30 mm, from 35 thick processing. |

2.9.Air path hydraulic system

●This machine adopts pneumatic and hydraulic actuators, operated by the panel, through the solenoid valve to execute, high degree of automation, reduce labor intensity. |

2.10.Electrical control system

● Adopt man-machine interface,PLC centralized control, advanced technology ● Man-machine interface, display and set the speed of the host machine, winding length, winding tension setting, taper setting. |